Dewetting Solder Meaning . solder dewetting is a common issue in soldering processes, particularly in electronics manufacturing, where solder joints lose their integrity and wetting ability, leading to a reduction in solder adhesion to the surfaces being soldered. dewetting is a serious problem with component parts, such as in solder joints or pads. dewetting in a solder joint indicates a problem with the solder pad or component part. dewetting is a type of process that occurs when solder pastes coat the terminals of the components and pads of pcb but then leave some parts. Solder will not bond with. Dewetting occurs when the molten solder does initially coat the component terminals and pcb pads but then recedes from these parts, leaving some thin areas of solder on the base metal and some irregular, thick clumps. what is the meaning of solder dewetting?

from absolutepcbassembly.com

Solder will not bond with. Dewetting occurs when the molten solder does initially coat the component terminals and pcb pads but then recedes from these parts, leaving some thin areas of solder on the base metal and some irregular, thick clumps. solder dewetting is a common issue in soldering processes, particularly in electronics manufacturing, where solder joints lose their integrity and wetting ability, leading to a reduction in solder adhesion to the surfaces being soldered. dewetting is a type of process that occurs when solder pastes coat the terminals of the components and pads of pcb but then leave some parts. what is the meaning of solder dewetting? dewetting is a serious problem with component parts, such as in solder joints or pads. dewetting in a solder joint indicates a problem with the solder pad or component part.

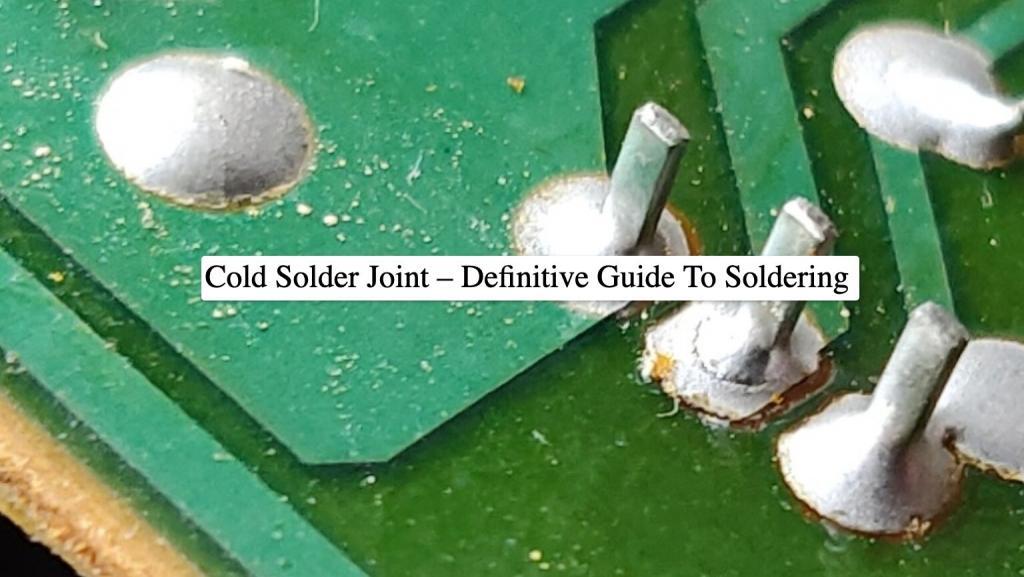

Cold Solder Joint Definitive Guide to Soldering Absolute Electronics Services

Dewetting Solder Meaning what is the meaning of solder dewetting? Dewetting occurs when the molten solder does initially coat the component terminals and pcb pads but then recedes from these parts, leaving some thin areas of solder on the base metal and some irregular, thick clumps. dewetting in a solder joint indicates a problem with the solder pad or component part. Solder will not bond with. solder dewetting is a common issue in soldering processes, particularly in electronics manufacturing, where solder joints lose their integrity and wetting ability, leading to a reduction in solder adhesion to the surfaces being soldered. dewetting is a serious problem with component parts, such as in solder joints or pads. what is the meaning of solder dewetting? dewetting is a type of process that occurs when solder pastes coat the terminals of the components and pads of pcb but then leave some parts.

From rushpcb.com

What is a Solder Joint? RushPcb Dewetting Solder Meaning Solder will not bond with. what is the meaning of solder dewetting? Dewetting occurs when the molten solder does initially coat the component terminals and pcb pads but then recedes from these parts, leaving some thin areas of solder on the base metal and some irregular, thick clumps. dewetting is a serious problem with component parts, such as. Dewetting Solder Meaning.

From www.pinterest.com

The Basics Of Soldering Explained [Infographic] Lifehacker Australia Soldering, Basic Dewetting Solder Meaning Dewetting occurs when the molten solder does initially coat the component terminals and pcb pads but then recedes from these parts, leaving some thin areas of solder on the base metal and some irregular, thick clumps. what is the meaning of solder dewetting? dewetting in a solder joint indicates a problem with the solder pad or component part.. Dewetting Solder Meaning.

From www.nextpcb.com

How to Do Through Hole Solder Well Dewetting Solder Meaning dewetting in a solder joint indicates a problem with the solder pad or component part. Dewetting occurs when the molten solder does initially coat the component terminals and pcb pads but then recedes from these parts, leaving some thin areas of solder on the base metal and some irregular, thick clumps. solder dewetting is a common issue in. Dewetting Solder Meaning.

From www.pcbdirectory.com

What is Solder Dewetting? PCB Directory Dewetting Solder Meaning solder dewetting is a common issue in soldering processes, particularly in electronics manufacturing, where solder joints lose their integrity and wetting ability, leading to a reduction in solder adhesion to the surfaces being soldered. Solder will not bond with. dewetting in a solder joint indicates a problem with the solder pad or component part. what is the. Dewetting Solder Meaning.

From llllllll.co

Soldering q's Tech lines Dewetting Solder Meaning Solder will not bond with. what is the meaning of solder dewetting? solder dewetting is a common issue in soldering processes, particularly in electronics manufacturing, where solder joints lose their integrity and wetting ability, leading to a reduction in solder adhesion to the surfaces being soldered. dewetting in a solder joint indicates a problem with the solder. Dewetting Solder Meaning.

From www.researchgate.net

Solder transfer layer dewetting. Download Scientific Diagram Dewetting Solder Meaning dewetting is a type of process that occurs when solder pastes coat the terminals of the components and pads of pcb but then leave some parts. Solder will not bond with. solder dewetting is a common issue in soldering processes, particularly in electronics manufacturing, where solder joints lose their integrity and wetting ability, leading to a reduction in. Dewetting Solder Meaning.

From www.youtube.com

Desoldering Soldering Basics Soldering for Beginners YouTube Dewetting Solder Meaning dewetting is a serious problem with component parts, such as in solder joints or pads. dewetting in a solder joint indicates a problem with the solder pad or component part. Dewetting occurs when the molten solder does initially coat the component terminals and pcb pads but then recedes from these parts, leaving some thin areas of solder on. Dewetting Solder Meaning.

From analyseameter.com

What is Soldering Iron and how to choose them Analyse A Meter Dewetting Solder Meaning Dewetting occurs when the molten solder does initially coat the component terminals and pcb pads but then recedes from these parts, leaving some thin areas of solder on the base metal and some irregular, thick clumps. what is the meaning of solder dewetting? dewetting is a serious problem with component parts, such as in solder joints or pads.. Dewetting Solder Meaning.

From smtnet.com

causes of solder dewetting SMT Electronics Manufacturing Dewetting Solder Meaning Solder will not bond with. solder dewetting is a common issue in soldering processes, particularly in electronics manufacturing, where solder joints lose their integrity and wetting ability, leading to a reduction in solder adhesion to the surfaces being soldered. dewetting is a type of process that occurs when solder pastes coat the terminals of the components and pads. Dewetting Solder Meaning.

From www.reddit.com

Not spreading in reverse The dewetting of a liquid film into a single drop r/science Dewetting Solder Meaning solder dewetting is a common issue in soldering processes, particularly in electronics manufacturing, where solder joints lose their integrity and wetting ability, leading to a reduction in solder adhesion to the surfaces being soldered. dewetting is a serious problem with component parts, such as in solder joints or pads. dewetting is a type of process that occurs. Dewetting Solder Meaning.

From www.youtube.com

Solder Wetting of Surface Mount IC during Reflow Soldering YouTube Dewetting Solder Meaning Solder will not bond with. dewetting is a serious problem with component parts, such as in solder joints or pads. dewetting is a type of process that occurs when solder pastes coat the terminals of the components and pads of pcb but then leave some parts. dewetting in a solder joint indicates a problem with the solder. Dewetting Solder Meaning.

From www.youtube.com

Nonwetting and Dewetting during Soldering PCB Knowledge YouTube Dewetting Solder Meaning dewetting is a serious problem with component parts, such as in solder joints or pads. dewetting is a type of process that occurs when solder pastes coat the terminals of the components and pads of pcb but then leave some parts. dewetting in a solder joint indicates a problem with the solder pad or component part. . Dewetting Solder Meaning.

From www.youtube.com

Soldering Soldering types Solder Specifications Good vs. Bad Solder Joints YouTube Dewetting Solder Meaning Solder will not bond with. what is the meaning of solder dewetting? dewetting is a type of process that occurs when solder pastes coat the terminals of the components and pads of pcb but then leave some parts. dewetting in a solder joint indicates a problem with the solder pad or component part. solder dewetting is. Dewetting Solder Meaning.

From www.researchgate.net

Sketch of the mechanism of solid state dewetting of a metal thin film... Download Scientific Dewetting Solder Meaning solder dewetting is a common issue in soldering processes, particularly in electronics manufacturing, where solder joints lose their integrity and wetting ability, leading to a reduction in solder adhesion to the surfaces being soldered. dewetting in a solder joint indicates a problem with the solder pad or component part. what is the meaning of solder dewetting? . Dewetting Solder Meaning.

From www.insituware.com

Insituware Definitive Guide to Solder Paste Dewetting Solder Meaning Dewetting occurs when the molten solder does initially coat the component terminals and pcb pads but then recedes from these parts, leaving some thin areas of solder on the base metal and some irregular, thick clumps. Solder will not bond with. dewetting is a type of process that occurs when solder pastes coat the terminals of the components and. Dewetting Solder Meaning.

From absolutepcbassembly.com

Cold Solder Joint Definitive Guide to Soldering Absolute Electronics Services Dewetting Solder Meaning dewetting in a solder joint indicates a problem with the solder pad or component part. dewetting is a type of process that occurs when solder pastes coat the terminals of the components and pads of pcb but then leave some parts. Dewetting occurs when the molten solder does initially coat the component terminals and pcb pads but then. Dewetting Solder Meaning.

From www.youtube.com

Hot Tips 3 Solder Wetting YouTube Dewetting Solder Meaning dewetting is a serious problem with component parts, such as in solder joints or pads. what is the meaning of solder dewetting? dewetting is a type of process that occurs when solder pastes coat the terminals of the components and pads of pcb but then leave some parts. dewetting in a solder joint indicates a problem. Dewetting Solder Meaning.

From exohuscdj.blob.core.windows.net

Solder Wick Grainger at Annie Bare blog Dewetting Solder Meaning what is the meaning of solder dewetting? Dewetting occurs when the molten solder does initially coat the component terminals and pcb pads but then recedes from these parts, leaving some thin areas of solder on the base metal and some irregular, thick clumps. Solder will not bond with. dewetting is a type of process that occurs when solder. Dewetting Solder Meaning.